Our Products

A Leading Manufacturing Company serving the Industry since 1991

Product Profile

Our state-of-the-art infrastructure is fully equipped with best machines and equipment to produce a range of quality products. This makes sure that we produce only the best quality products and exceed our clients' expectations. Our clients are located in different parts of India.

Product Standards & Manufacturing Process

We fabricate a wide range of Nuts, Precision Machined Components, We use high grade steel, alloy steel, mild steel, and other metals to present precisely engineered tools and components. The raw material used is sourced from reliable vendors located in Mumbai and Ahemedabad. We ascertain the quality of the raw material by acquiring test certificate from the dealer before accepting the material.

- High tolerance and tensile strength

- Sturdy and hard-wearing

- Longer and efficient performance

We Manufacture Good Quality & Wide Variety of Nuts

Our Products

- All

- Hex Nut

- High Tensile Nut

- Square Nut

- Round Nut

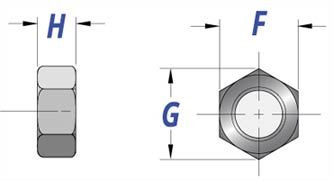

DIMENSION IN ACCORDANCE WITH REVISED STANDARDS

METRIC SERIES

| THREAD SIZE | PITCH | WIDTH ACROSS FLATE "F" | WIDTH ACROSS CORNER "G" | THICKNESS OF NORMAL NUTS "H" | |||||||

| MAX | MIN | MIN | MAX | MIN | |||||||

| M4 | 0.7 | 7.00 | 6.78 | 7.66 | 3.20 | 2.90 | |||||

| M5 | 0.8 | 8.00 | 7.78 | 8.79 | 4.00 | 4.70 | 3.70 | 4.40 | |||

| M6 | 1.0 | 10.00 | 9.78 | 11.05 | 5.00 | 5.20 | 4.70 | 4.90 | |||

| M8 | 1.25 | 13.00 | 12.73 | 14.38 | 6.50 | 6.80 | 6.14 | 6.44 | |||

| M10 | 1.5 | 17.00 | 16.00 | 16.73 | 15.73 | 18.90 | 17.77 | 8.00 | 8.40 | 7.64 | 8.04 |

| M12 | 1.75 | 19.00 | 18.00 | 18.67 | 17.73 | 21.10 | 20.03 | 10.00 | 10.80 | 9.64 | 10.37 |

| M14 | 2.0 | 22.00 | 21.00 | 21.67 | 20.67 | 24.49 | 23.35 | 11.00 | 12.80 | 10.57 | 12.10 |

| M16 | 2.0 | 24.00 | 23.67 | 26.75 | 13.00 | 14.80 | 12.57 | 14.10 | |||

INCH SERIES

| THREAD SIZE | T.P.I. | WIDTH ACROSS FLATE "F" | WIDTH ACROSS CORNER "G" | THICKNESS OF NORMAL NUTS "H" | |||||

|---|---|---|---|---|---|---|---|---|---|

| BSW | BSF | UNC | UNF | MAX | MIN | MAX | MAX | MIN | |

| 1/4" | 20 | 28 | 0.437" | 0.430" | 0.505" | 0.224" | 0.214" | ||

| 20 | 26 | 0.445" | 0.438" | 0.510" | 0.200" | 0.190" | |||

| 5/16" | 18 | 22 | 0.525" | 0.518" | 0.610" | 0.250" | 0.240" | ||

| 18 | 24 | 0.500" | 0.493" | 0.557" | 0.271" | 0.261" | |||

| 3/8" | 16 | 20 | 0.600" | 0.592" | 0.690" | 0.312" | 0.302" | ||

| 16 | 24 | 0.562" | 0.554" | 0.650" | 0.333" | 0.323" | |||

| 7/16" | 14 | 18 | 0.710" | 0.702" | 0.820" | 0.375" | 0.365" | ||

| 14 | 20 | 0.687" | 0.679" | 0.794" | 0.380" | 0.370" | |||

| 1/2" | 12 | 16 | 0.820" | 0.812" | 0.950" | 0.437" | 0.427" | ||

| 13 | 20 | 0.750" | 0.742" | 0.866" | 0.442" | 0.432" | |||

| 9/16" | 12 | 16 | 0.920" | 0.912" | 1.060" | 0.500" | 0.490" | ||

| 12 | 18 | 0.875" | 0.867" | 1.010" | 0.490" | 0.480" | |||

| 5/8" | 11 | 14 | 1.010" | 1.000" | 1.170" | 0.562" | 0.552" | ||

| 11 | 18 | 0.937" | 0.929" | 1.083" | 0.552" | 0.542" | |||